At Hitachi Global Air Power, we understand that your air compressor is a significant investment, critical to your operations. That’s why we’ve established a series of state-of-the-art Compressor Air End Rebuild Centres across Australia, offering nationwide service by factory-trained Compressor Air End Rebuild Technicians who are experts in their field and dedicated to maximising the longevity and efficiency of your assets.

Extend the Life of Your Compressor with Air End Rebuilds

At the heart of every rotary screw compressor is the air end – the component responsible for compressing air and driving overall performance. Over time, your compressor’s Air End – like any mechanical component – experiences gradual wear, which can lead to reduced efficiency or even failure. But replacing the entire compressor isn’t always necessary or cost-effective.

That’s where our Hitachi Global Air Power Compressor Air End Rebuild and Service Exchange Program comes in. We offer tailored options focused on restoring your compressor’s air end and extending the life of your asset- a solution designed to suit your unique compressor requirements.

Our rebuild solutions support a circular economy by prioritising air compressor repair, reuse, rebuild, and remanufacture. This not only extends the life of your compressor but also significantly reduces the resource use and emissions involved in manufacturing and disposing of a full unit.

Discover the Air End Rebuild Centre experience

Imagine bringing your air compressor back to “like-new” condition, but without the cost of a full replacement.

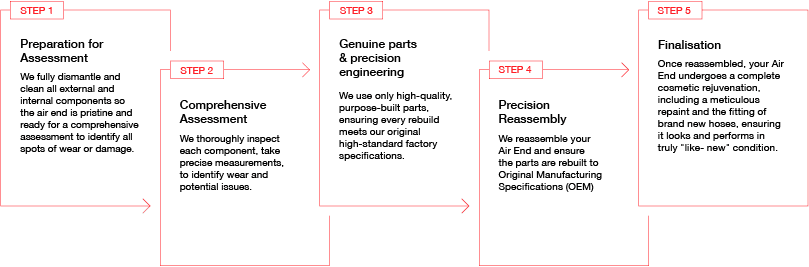

Our team of expert, factory-trained technicians, equipped with tools and diagnostic equipment, specialise in rebuilding and restoring worn out air ends to “like-new” condition.

Our Compressor Air End solutions

Our solutions are built to keep your operations moving – offering the most economical way to extend your compressor’s life, backed by specialist expertise and fast turnaround you can rely on.

Air End Service Exchange: Get back up and running, fast

Replacing a compressor can be a costly exercise – not just in equipment cost, but also in installation and the downtime that disrupts your operations. That’s why we offer our Compressor Air End Service Exchange Program: a fast, cost-effective alternative. Simply exchange your old air end for a new or refurbished one, right off the shelf at your local service centre. This means significantly less downtime for your compressor, getting your operations back up and running sooner.

Customised Air End Rebuild: Precision, performance, and peace of mind

Every compressor has its own story, and we believe its rebuild should too. Our customised Air End Rebuild service is tailored precisely to your unit. We use genuine parts and apply our deep technical expertise, precision-engineering each component to meet original factory specifications. It’s a smart, economical choice that revitalises your existing equipment, extending its lifespan and restoring peak performance without the significant capital outlay of a brand-new compressor. Plus, our optional loan compressors ensure your air needs are met continuously, preventing delays, downtime, or disruption.

Why compressor Air Ends matter

The Air End is the heart of your compressor. As it wears, efficiency drops, and breakdowns can occur. But don’t rush to replace the entire unit! Often, simply servicing or replacing the air end saves you significant time and money, getting you back up and running faster. It’s the smarter, more cost-effective solution.

Is your Air End Failing? Here’s What to Watch For:

Over time all compressor Air Ends experience wear – especially in demanding environments like heat, humidity, or dust. As tolerances increase, coatings degrade, and screw geometry wears down, your compressor works harder, consuming more energy and increasing the risk of failure. To avoid rising energy costs and unexpected downtime.

Keep an eye out for these common indicators:

- Compressor age / high run hours:

- Reduced air output

- Lower efficiency/higher energy bills

- Unusual noise and vibration

- Oil leaks or contamination

- Higher operating temperatures

If you have concerns about any of the above, reach out to the team using the form below to discuss if an Air End rebuild is a good option for your compressor.

By choosing Hitachi Global Air Power Australia, you gain access to expert technicians, genuine parts, and precision-engineered rebuilds designed to restore performance and reduce downtime.

Contact Us

We’re Here to Help

Speak to the team about your servicing and parts needs.