Mines in the most remote parts of Australia represent some of the harshest, most demanding workplaces on earth. With drilling equipment used at almost every stage of a mine’s operations, compressed air becomes the essential driver of operations and consistent supply provided by reliable air compressors is critical.

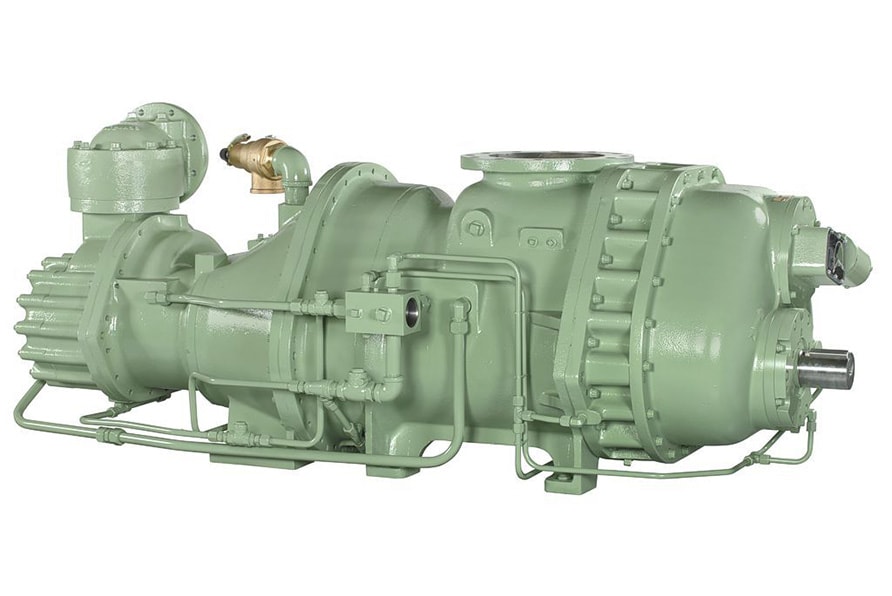

The internal compressor and the air end within it become the hardest working piece of equipment on site. Every screw compressor is fundamentally dependent on the air end for its primary function, which represents a situation of extraordinary risk, given the high stakes.

While air compressors can be monitored thanks to a manufacturer determined life cycle (and good record keeping), this is rarely the case with air ends. The first indication of an issue with an air end – even slight deterioration – will be impaired compressor function. Every metre of drilling comes at a cost and just minutes of downtime can result in eye watering losses. Quentin Sanders, Leading Hand Air End Technician for Sullair Australia explains. “With an air end there’s no set hours as to how often they should be changed out. Certain companies will change out at 12 to 15,000 hours, as an industry standard, but the rotating components, bearings and so on only have a certain shelf life. No manufacturer can put a lifespan on that because each compressor is different, as is the quality of servicing, the impact of foreign bodies and oil degradation.”

Support that provides fast and customised solutions is essential, which is what makes Sullair’s Air End Exchange Program so vital to the Australian market.

The exchange process is fairly straightforward, and by design provides an agile and efficient response to dealing with faulty air ends – through repair, customisation or replacement.

Gareth Spencer is Sullair’s Regional Sales Manager for WA, SA and the NT – challenging locations, where being responsive to air end faults is particularly crucial. “When an air end isn’t working as well as it should, it can be brought into an air end centre, be repaired or exchanged for one that’s already been repaired or had replacement parts fitted, then we take the faulty air end and rebuild it internally”.

Decisions are made on a case by case basis, with the ideal solution implemented, based on what stage of drilling the compressor is functioning at, and what shape the part itself is in. A customisation that increases pressure but reduces flow, or vice versa may be all that’s required. Alternatively, the long game becomes the priority and a new part that offers thousands of hours extension to life is the most compelling solution.

Gareth explains how these decisions are made. “There’s two stages to air end function – the low-pressure stage and the high-pressure stage. The latter is where all the real hard work is done, so when it’s working with pressures between 350psi up to 500, we’d replace a part for a new one, rather than repair”. That 2nd hand part can then be repaired and resold.

Having parts on hand ensures problems are solved quickly with genuine expertise. Across Sullair’s four regional centres, in Melbourne, Newcastle, Mackay and Canningvale, a deep knowledge of the local context ensures air end issues can be dealt with thoroughly and efficiently.

“Sullair compressors are synonymous with the environment,” says Quentin. “They will continue to work in extremely harsh conditions – 50+ degree days, running flat stick, drilling down for metres and metres, on a site that’s hundreds of kilometres from the next town”.”

Working in such high-risk environments necessitates highly skilled staff, and Sullair supports all of its customer base with training and technical guidance as standard. With technicians in all of Sullair’s regional facilities responding to driller questions as part of day to day operations – intel is part of the service. The provision of technical expertise and support puts preventative maintenance practices in place on sites, enabling everyone to implement solutions that ensure the utmost safety measures are in place and seamless production cycles are sustained. From a health and safety perspective, further training is also of particular importance. In recent years, Sullair has established a strong reputation for its comprehensive on site training delivery.

“The training side is really beneficial,” explains Quentin. “Because the guys on site understand how imperative it is to know the equipment. They’ll buy equipment and spare parts from us and we make sure they have the knowledge to maintain their gear, plus they’re then encouraged to use genuine parts”.