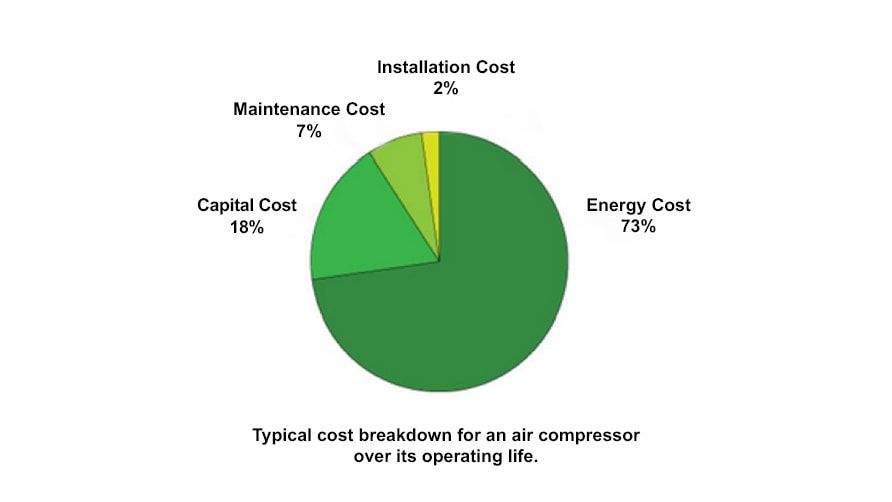

The ongoing costs of retaining an ageing compressor must be factored into decision making in any facility. Compressed air systems account for up to 10% of all of Australia’s industrial electricity use, and the air compressor is often the largest single source of energy consumption in a manufacturing facility.

“Across industry we see stubbornly high energy prices, so it’s important to have the most efficient compressed air solution, correctly sized to your business needs and maintained in line with OEM recommendations”, explains Sullair Australia Managing Director Fred Funnell.

All equipment has a manufacturer-determined life cycle, calculated in hours, and clearly stated in product manuals. If an air compressor has an effective working life of 80,000 working hours, that might translate into a 10-year lifespan for 24 hours a day, year-round usage, or a 20-year life span for half of that. If a compressor is close to, or at the end-of-life stage, decisions around whether to repair or replace become more critical. “Not everyone’s running 24/7 for 365 days a year,” explains Head of Aftermarket at Sullair, Steve Cowburn. “If the manual states a service is needed at 60,000 hours, then any potential issues can be picked up well within the machine’s life span and not at the end of life, when it might be too late.”

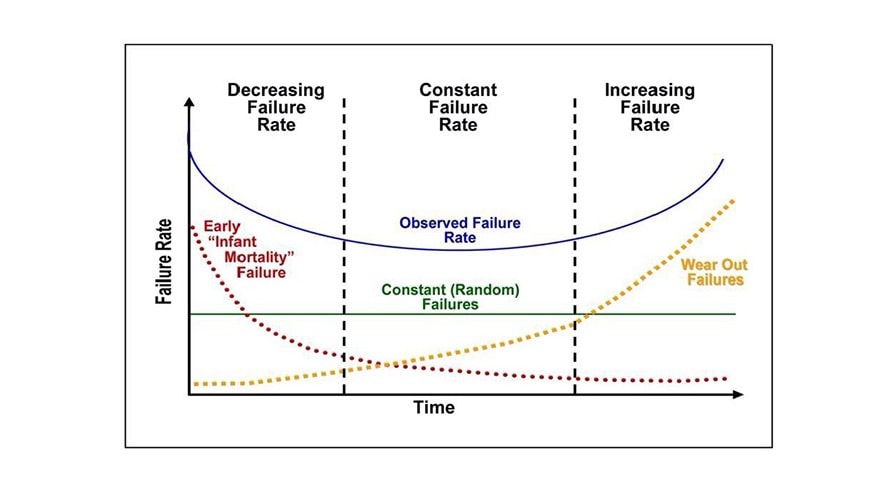

The bathtub curve

Let’s review a familiar concept across industry: the bathtub curve. This measure of reliability across the lifespan of, in this case, a piece of equipment, is especially important to those managing high end equipment, critical to production schedules.

The bathtub curve deals with 3 stages within a product’s life cycle. The first stage deals with early issues stemming from the build or workmanship of new equipment, shortly after purchase – the curve slopes downwards. These ‘infantile failures’ are often covered under warranty and easily resolved via tech support, service, or replacement parts. Once infantile failures are dealt with, quality equipment should seamlessly transition into the next stage of non-events: the curve flattens out (like the base of a bathtub) and the machine functions to its capacity for much of its working lifetime, without incident.

Steve Cowburn explains what this looks like from a service team’s perspective. “When techs do regular service, there are about 11 or 12 factors they measure – temperature, pressures, vibrations and so on. If these things measure normal at every service, the bottom of the bathtub curve is sustained. If we start seeing a trend in increased failure across these factors we know there’s an issue developing and the curve starts to trend upwards”. This is where the third ‘end of life’ stage kicks in and is where the decisions around repair or replacement of equipment became more complex, for many businesses. “The choice will almost always be to repair if the cost difference between the two is wide,” says Cowburn. “The closer a repair cost gets to the replacement cost, the more likely a customer will be to replace.” The timing of end-of-life equipment issues can never be worse if the failure is unpredictable.

Having a clear sense of the bathtub curve with regard to the equipment being managed is imperative to predicting how long repairs can extend the life of the equipment for, and when a replacement will be required, and CapEx spending needs to be factored into the budget. Unsurprisingly, businesses that make scheduled servicing of compressors a key priority have been able to transition more seamlessly through challenging periods: they recognise services are a key risk mitigation tool.

A business’s compressor dependency varies according to its size and its ongoing compressed air needs. Smaller operations might have more flexibility to juggle jobs whilst a replacement part is ordered, delivered, and installed; while larger operations usually have complex backup systems in place that kick in, in the event of machinery faults or failure.

The more mission critical air supply is, the more likely you are to have a backup supply. How a business manages its compressor function depends on the criticality of it to that business’ operations. The more critical the equipment, the more scrutinised these decisions become. Compressed air that goes down can be a huge liability, with losses in the millions if just one day of production is impacted.

A comprehensive customer care and preventative maintenance plan becomes an essential tool in your operations so that scheduled servicing, awareness of your equipment’s life span and budgeted equipment expenditure are ideally considered, forecasted, and planned for.