For many businesses, a reliable compressed air supply is critical to its survival. Not only to sustain day to day operations, year in year out, but also in times of crisis. The events of 2020 delivered many revelations – from who the ‘essential’ staff really are, to how easy it can be to shift from core business to a relevant needs-based alternative – hand sanitiser anyone?

In any event, a diversion from the norm, or an escalation above and beyond standard operations, removes the usual margin for error, and operations teams find themselves in increasingly problematic situations. Interruptions or breakdowns of production can have devastating consequences. The need for high quality, clean and uninterrupted supply of compressed air, at the standard capacity, or at higher volumes than usual becomes paramount.

Pivoting out of the worst case scenario

With ‘pivot’ emerging as the buzzword of 2020, businesses have been given an opportunity to re-evaluate their pre-pandemic operations, assess how they transitioned through the many and varied challenges of restrictions and think creatively about a new way forward. As the first half of the 2020 financial year drew to a close, attention started to shift from how to get through the crisis, to what fundamental operational changes needed to be made, to secure a business’s recovery and survival over the long term.

Economic forecasts for the years ahead are grim to say the least. A recent piece from The World Bank certainly made for sober reading. “Over the longer horizon, the deep recessions triggered by the pandemic are expected to leave lasting scars through lower investment, an erosion of human capital through lost work and schooling, and fragmentation of global trade and supply linkages”. There’s nothing like a low confidence business environment to force a reassessment of priorities.

Reframing risk assessment and management

Businesses have to make tough decisions going forward: not only to secure their capacity to transition through more challenging periods ahead, but also to consider how immediate actions might impact on the viability of operations in the longer term. Marketplace uncertainty across industry often results in an increased wariness, especially where significant CapEx investments are concerned and this will surely be sustained in the years to come.

Sullair Australia’s Managing Director, Fred Funnell foresees stringent management of operational costs as critical. “The need for strong cash management has been magnified and subsequently greater pressure placed on profit margins. It’s more essential than ever there’s no exposure to unplanned costs.”

The outsourcing tipping point

So where do we begin with regard to ‘doing things differently’? Instinctively this question prompts thoughts of innovation and new grand ideas, however there are great historic examples of what we now consider as ‘pivoting’, to be drawn from. The most easily relatable must be that of the humble office photocopier. An essential piece of equipment in every office it, along with the printer, survived the digital revolution, the ‘paperless office’ period and more. Today printing and copying machines still exist in greater size and number than ever before, thanks to the home office, 3D technology and online procurement services.

Technology around these workhorses of the 1980s evolved as demand for them grew. Printers and photocopiers became ubiquitous in offices across the globe, but the shared pain point was the high ownership and running costs. The equipment grew increasingly laborious to maintain, not to mention the costly expense of repair, replacements and upgrades as technology changed (from a laser printer to an inkjet for example, with a photocopier as additional necessary hardware). A shift in thinking was inevitable – enter the multifunction machines – printers that also copied, scanned, faxed and gifted us with the office Christmas party bum print.

Providing numerous solutions in a single machine, this streamlined the offering, but came with even greater maintenance needs and costs. Office printing solutions became a burdensome capital expense – in hindsight a stage that could be seen as the tipping point. With printer manufacturers and suppliers registering decreased sales of equipment and increased service and maintenance costs, the pivot seemed obvious and ‘outsourcing’ became one of the key business strategies of the 90s.

By forming a strategic partnership with printer suppliers, businesses could secure the essential equipment they needed, packaged with expert technical service and maintenance, while saving on CapEx spending. The mental load was transferred to the experts, enabling organisations to shift their focus back to their core business.

Fast forward to today and many businesses are now seamlessly integrating similar innovations, in response to the new landscape. The demand for quick and streamlined solutions is heightened across industries, coupled with a more open-minded approach to getting things done safely, with cost and production efficiencies as the very highest priority.

Better the devil you know – to repair or replace?

Decisions around equipment management are complex, across all industries, now more than ever. In a business as usual environment, a conscientious approach to making these decisions should always involve a thorough analysis of the costs involved, the pros and cons and the critical operational requirements. Scheduled servicing, knowing the equipment life span and budgeted equipment expenditure are ideally considered, forecasted and planned for. Those in charge of operations in the months ahead will find themselves having to review the realities around sustaining production, while growing market uncertainty chips away at their confidence – or even capacity – to invest in capital purchases. Timing has become everything and those with a solid understanding of their equipment, where it’s at in its life span and its condition in any given month, will certainly have the competitive advantage to make informed choices.

When CapEx plans around replacing end of life equipment or investing in new projects are shelved, back-up solutions must be found. Repairing rather than replacing equipment pressures machinery to work longer and harder than is optimal. It also places the business in an increasingly unreliable and costly loop, in terms of ongoing operation, maintenance and energy usage. Funnell explains “When you’re operating with reduced margins, perhaps because end user demand has declined or competitive pressures have reduced margins, you can’t afford to have an unplanned outage on your production line. Even a shift or two offline may be your profit for the month gone”.

The bathtub curve

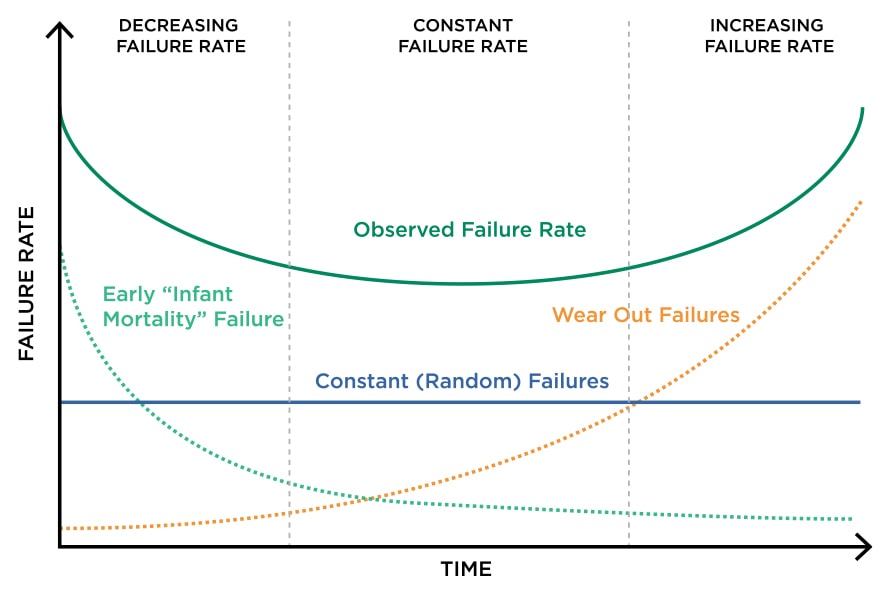

To break this down in a more conceptual way, let’s review a familiar concept across industry: the bathtub curve. A measure of reliability across the lifespan of, in this case, a piece of equipment, its relevancy has become starkly obvious, to those managing high end equipment, critical to production schedules, especially during the COVID-19 shutdowns.

The bathtub curve deals with 3 stages within a product’s life cycle. The first stage deals with early issues stemming from the build or workmanship of new equipment, shortly after purchase – the curve slopes upwards. These ‘infantile failures’ are often covered under warranty and easily resolved via tech support, service, or replacement parts. Once infantile failures are dealt with, quality equipment should seamlessly transition into the next stage of non-events: the curve flattens out (like the base of a bathtub) and the machine functions to its capacity for much of its working lifetime, without incident.

The ‘bathtub curve’ hazard function (blue, upper solid line) is a combination of a decreasing hazard of early failure (red dotted line) and an increasing hazard of wear-out failure (yellow dotted line), plus some constant hazard of random failure (green, lower solid line).

Image and caption source: Wikipedia

Head of Aftermarket at Sullair, Steve Cowburn explains what this looks like from a service team’s perspective. “When techs do regular service, there are about 11 or 12 factors they measure – temperature, pressures, vibrations and so on. If these things measure normal at every service, the bottom of the bathtub curve is sustained. As soon as one of those factors changes consistently across services, we know there’s an issue developing”. This is where the third ‘end of life’ stage kicks in and has been where the decisions around repair or replacement of equipment became more complex, for many businesses during the shutdown. “The choice will almost always be to repair if the cost difference between the two is wide,” says Cowburn. “The closer a repair cost gets to the replacement cost, the more likely a customer will be to replace.” The timing of end of life equipment issues can never be worse if the failure is unpredictable.

Having a clear sense of the bathtub curve with regard to the equipment being managed is imperative to predicting how long repairs can extend the life of the equipment for, and when a replacement will be required and CapEx spending needs to be factored into the budget. Unsurprisingly, businesses that make scheduled servicing of compressors a key priority have been able to transition more seamlessly through challenging periods: they recognise services are a key risk mitigation tool.

The hidden costs of ageing compressors

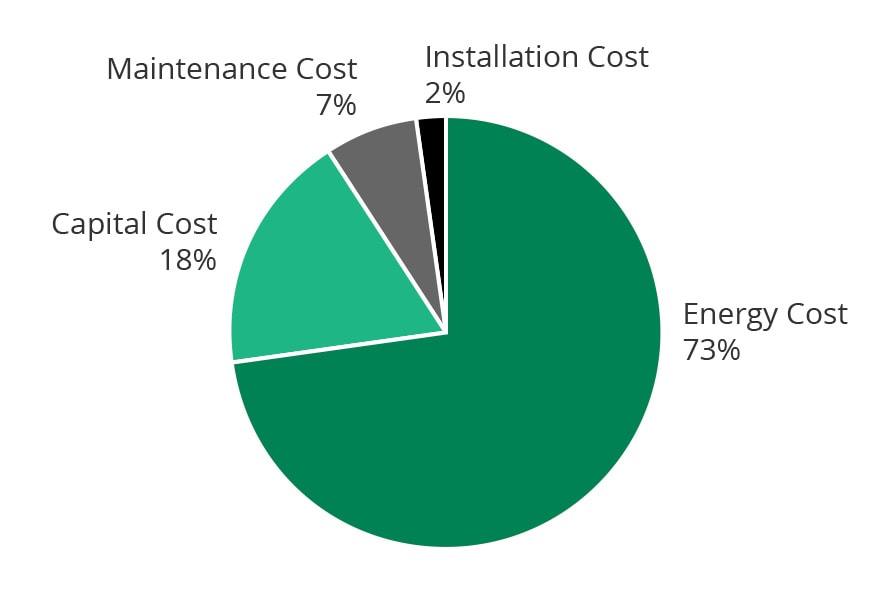

Additionally, the ongoing costs of retaining an ageing compressor must be factored into decision making. Compressed air systems account for up to 10% of all of Australia’s industrial electricity use, and the air compressor is often the largest single source of energy consumption in a manufacturing facility1. “Across industry you’re seeing stubbornly high energy prices, so it’s important you have the most efficient compressed air solution, correctly sized to your business needs and maintained in line with OEM recommendations”, explains Funnell.

Typical cost breakdown for an air compressor over its operating life.

Source: “My compressor has failed! Repair or Replace?” Steve Cowburn

All equipment has a manufacturer-determined life cycle, calculated in hours and clearly stated in product manuals. If an air compressor has an effective working life of 80,000 working hours, that might translate into a 10-year lifespan for 24 hour a day, year-round usage, or a 20-year life span for half of that. If a compressor is close to, or at the end of life stage, decisions around whether to repair or replace become more critical. “Not everyone’s running 24/7 for

365 days a year,” explains Cowburn. “If the manual states a service is needed at 60,000 hours then any potential issues can be picked up well within the machine’s life span and not at end of life, when it might be too late.”

A business’s compressor dependency varies according to its size and its ongoing compressed air needs. Smaller operations might have more flexibility to juggle jobs whilst a replacement part is ordered, delivered and installed; while larger operations usually have complex backup systems in place, that kick in, in the event of machinery faults or failure.

The more mission critical air supply is, the more likely you are to have a backup supply. How a business manages its compressor function depends on the criticality of it to that business’s operations. The more critical the equipment, the more scrutinised these decisions become. Compressed air that goes down can be a huge liability, with losses in the millions if just one day of production is impacted.

The compelling benefits of outsourcing compressed air solutions

The questions raised about repairing, reconditioning, or proceeding with replacement of equipment have different answers across industry, as no two businesses are alike. The need for an alternative approach that’s efficient, streamlined and cost effective becomes undeniable. This is where the compelling benefit to outsourcing comes in. The ability to make the necessary decisions around the business’s needs, whilst avoiding capital outlay for new equipment altogether makes it an extremely attractive solution.

Recognising the pain points of its customers during the pandemic period has been crucial for Sullair and they responded quickly by developing MAP – a Managed Air Power option that enables compressed air solutions to be completely outsourced. “COVID-19 has allowed us to experiment with different ways of running a business, in a very accelerated form,” says Funnell. “What it’s shown us, is how flexible businesses can be and how doing things differently can yield real benefits. MAP is one more way you can operate differently and achieve a better outcome.”

MAP provides a mechanism to ensure a customers’ compressed air needs are addressed, without a significant upfront capital outlay. Continuity of supply is improved and operations resume, knowing down time and costs are minimised. This is achieved by delivering an integrated new equipment and maintenance package over an agreed time frame.

In an outsourced solution such as this, the supplier also provides the expertise needed to manage the business’s compressed air supply; taking care of things that should be front of their mind, not the customer’s. Outright equipment purchases often put the responsibility for a deep understanding of the machinery, on the customer. In a time of fear and uncertainty, the built-in level of additional support, of a product like MAP becomes so much more than an added bonus. The technical expertise of the support also adds a deeper layer to the value proposition of the investment. Sullair has prioritised their service delivery to focus on the provision of expertise that guides and supports customers to a viable and customised solution.

“As excellent and well credentialed as your staff can be, they’re not professional compressor technicians. They don’t spend their whole day diagnosing the faults with the machines and they haven’t been factory trained,” says Funnell. “Many companies have implemented cost cutting programs, and though the drivers for replacement remain the same, the capacity of companies to fund that replacement has decayed through the COVID event. What an offering like MAP provides is great certainty in terms of forward monthly payments, as well as removing that significant cash draw down on commissioning. It fundamentally means customers can smooth out their cash flow over the 5-year contract period”.

It can be hard to recognise there might be positive outcomes from all that was of 2020, but one is surely the opportunity presented to reflect on the fundamentals of a business’ operations. With core business put under the harshest light in the leanest of conditions, a brutal reassessment of all that had been before has been unavoidable. For those with critical dependency on compressed air, as the dust settles and the long road ahead starts to reveal itself, there is inspiration in the chance provided to transform the status quo and embrace new solutions.

For more information about Sullair’s Managed Air Power (MAP) service or to book an appointment with a sales engineer to discuss further, please go to sullair.com.au/managed-air-power

- My compressor has failed! Repair or Replace? Steve Cowburn