Air compressors come in all shapes and sizes: scroll, reciprocating, rotary screw, centrifugal and more. But no matter the type, their mission remains the same – air compression to increase pressure to the desired level. However, different types of compressors have slightly different ways of compressing air. And it actually matters! It all comes down to the specific purpose you have in mind for that compressed air.

When it comes down to air compressor basics, they all follow a basic compression process, with some variables between models. These variations can, however, put a cap on what you can do with the compressed air. So, picking the right compressor type is like choosing the perfect tool for the job. Hitachi Global Air Power has a wide range of air compressors to meet your needs.

Before we dive deeper into the compression process, let’s take a quick look at how these air compressors get their power.

Introduction to air compressors – power sources

Compressed air is a mighty power source for air tools and various instruments. But the compressor itself needs power, too. The most common power sources for these compressors include:

- Petrol engines: these are ideal for smaller outdoor compressors, these portable units with wheels offer easy manoeuvrability, like a ‘suitcase on wheels’ in the compressor world.

- Diesel engines: dominating larger outdoor compressors in commercial construction projects, these portable air compressor tow-behind units and fixed-location compressors provide high energy efficiency, surpassing their petrol-fueled counterparts.

- Electric motors: when it comes to indoor compressors, electric motors take the stage, powering a wide range of applications, from home projects to heavy-duty industrial processes in large manufacturing plants.

Oil lubricated vs oil free compressors

When it comes to compressors, they can be divided into two types: oil-lubricated or oil-free.

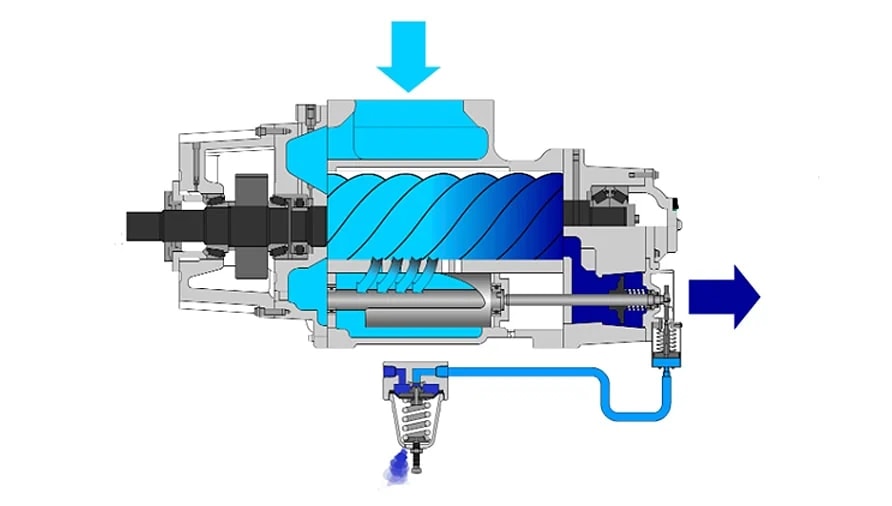

Oil-lubricated compressors (or oil-flooded compressors in the case of screw compressors) rely on oil within the compression chamber or for lubrication of pistons in the case of reciprocating machines. This oil pulls double duty as a lubricant, sealant, and coolant. But a tiny bit of that oil can enter the compressed air, which may not be ideal, depending on your air compressor usage.

On the flip side, we have oil-free compressors, which don’t use oil in the compression chamber and therefore, contamination of compressed air with oil is avoided. It’s worth noting oil might still be used elsewhere in the compression mechanism. Parts like bearings need a dash of oil to operate smoothly.

The Basics of Air Compression

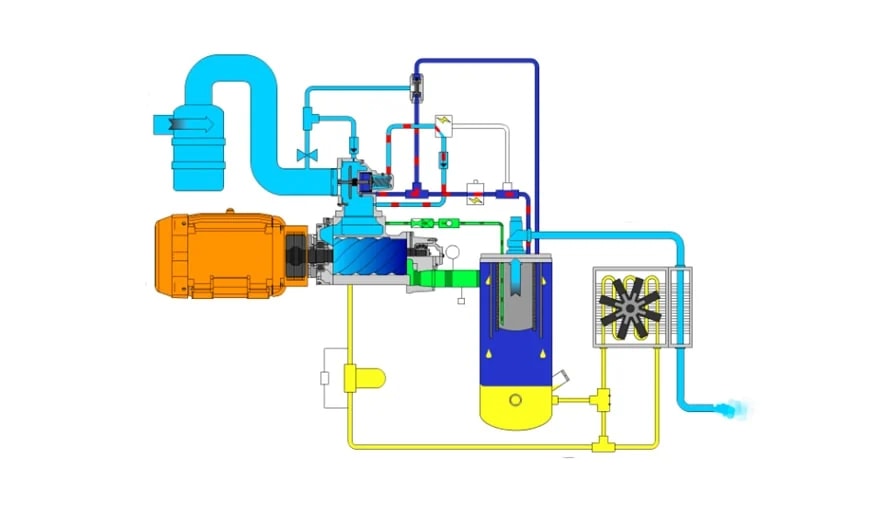

So, how does an air compressor work? Well, the air compression process involves several key stages: intake, compression, integrated storage, integrated cooling, and discharge. However, it’s important to note not all compressors require integrated storage or cooling.

1. Intake

The first thing needed to generate compressed air is, you guessed it, air. So, the first part of the process is air intake – air is drawn into the compressor through an air inlet valve and a filter before the air inlet valve acts as a guardian, preventing unwanted contaminants from entering the compressor.

2. Compression

Here, air flows into the compression chamber to be compressed. Compression refers to the alchemical process of harnessing the kinetic energy from the power source and converting it into the potential energy of pressurised air. A couple of crucial concepts, displacement and compressor type, apply to all compressors.

- Displacement: Compressors get the job done in two ways: positive displacement and dynamic displacement (also known as non-positive displacement). Positive displacement compressors are all about reducing the air volume to crank up the pressure. Meanwhile, dynamic displacement compressors take an active approach. They ramp up the air velocity, pumping up its kinetic energy and then slowing things down to boost that pressure.

3. Integrated Cooling

When we compress air, things can get pretty hot. While it’s not mandatory to cool the air before it exits the compressor, many electric compressors and some diesel compressors come equipped with nifty integrated aftercoolers. These aftercoolers work their magic by lowering the air temperature before it leaves the compressor.

A bonus feature is that compressors with aftercoolers often come with water separators too. These handy separators catch any excess moisture that condenses during the cooling process.

4. Discharge

At this final stage, the air passes through the discharge valve. Depending on the scenario, it might take a direct route to its destination or detour through a sequence of receivers, dryers and filters before reaching its final stop. Either way, it ensures the air is all set and ready for its designated purpose.

5. Storage

After the air goes through compression, it might take a detour into a receiver tank (also known as a storage tank or an air tank), depending on the type of compressor. The reasons for storage vary depending on the compressor type, but let’s cover a couple of common ones that apply to multiple types:

- Limited-duty cycle compressors, the ones not designed to run non-stop, make use of storage. This way, even during their downtime, you still have a supply of air ready to go.

- Modulating compressors, on the other hand, have smart controls that allow them to run below full capacity. They utilise storage to ensure a steady air stream when operating at reduced levels.

- Adding a storage tank also allows for increased time between the loading and unloading of compressors (where applicable) to improve the working life of the compressor

Consult an expert before buying.

Understanding how compressors operate is valuable in determining the suitable type for your application. However, there’s more to take into account than just the mechanics. Factors like energy efficiency, projected uptime, air compressor repairs and air compressor service all play a crucial role. That’s where your local Hitachi Global Air Power branch comes in. With their expertise and experience, they can guide you in selecting the perfect Hitachi air compressor that ticks all the boxes for your unique requirements.