You know you have great equipment when you can turn it on and forget about it. However, even the best machines need attention, so how do you protect your operations?

The application of centrifugal compressors across industries is broad – they are used throughout the automotive, oil and gas, pharmaceutical, chemical and electronics sectors, and within food and beverage production, heavy-duty manufacturing, aerospace high-technology manufacturing, and utilities/power generation. They are low-maintenance, energy-efficient solutions that produce the class zero oil free air that keeps these industries alive.

Despite being considered some of the most robust, reliable, and durable machines in the business, they still require regular servicing to keep them optimised. Care and attention from the most experienced professionals in the field is key. Centrifugal compressors are a unique type of compressor that operate at significant speeds and require a strong engineering mindset to understand the nuances of their function.

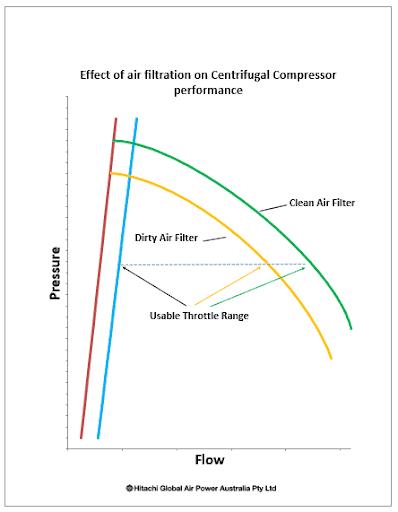

Before the experts get called in however, owner-operators will already have been taking care of daily checks as a matter of course. This includes things like condensate checks, data logs, morning and afternoon shift oil sampling and oil level checks, differential pressure checks across the inlet filters, greasing the motors, and general observation of the machines. “Checks like these need to happen every day just to maintain the status quo of your compressor”, explains Trevor Hicklin, Business Development Manager for the Centrifugal Service Division at Hitachi Global Air Power Australia. “Daily checks give reassurance and indications that everything is operating as it should”. Checks like these won’t prevent build-up or detect every possible issue, though. “All the checks may come back fine, and you may see little change in performance”, says Trevor. “But compressors don’t offer clear indications of what’s happening when issues arise”. This is what makes those daily checks essential. “As soon as alterations in daily results occur, that’s when you need to reach out to your service teams for support”. The centrifugal team is available to guide you and recommend a service schedule that is appropriate for your needs.

In good news for all compressor owners, Hitachi Global Air Power Australia’s Centrifugal Service Division has the knowledge base to service all brands of centrifugal compressors. “Given the specialised nature of centrifugal compressor servicing”, says Trevor, “being able to offer support to competitor machines is crucial in the Australian market, so everyone nationally is looked after.”

The secret to outstanding centrifugal compressor performance is service people who know their equipment. Experienced service ensures you’ll achieve the best performance possible from your machine. At Hitachi Global Air Power, our service team believes that any equipment is only as good as the attention it’s given. We put our best people on the job so your centrifugal compressor gives the best performance possible.

Our health check assesses the performance and integrity of your centrifugal compressors and identifies the actions required to return your equipment to its optimal performance. A health check will help set your equipment up for seamless operation throughout its lifetime.

Our service team is dedicated to helping you get the best performance possible from your equipment. Today, and always.

Enquire now

Book in with us for a free health check* today.

*Hitachi Global Air Power’s health checks are generally free of charge, but additional costs may occur and will be assessed and advised at the time of booking.