By Trevor Brathwaite and Sullair Australia

It’s more than likely you’ve seen one – you just may not know of them by name. If you have owned or serviced a Sullair air compressor or vacuum pump at some point, you will have seen pneumatic pressure regulators before in various shapes and sizes.

So, what’s their purpose?

Let’s start with the purpose. The purpose of a pressure regulator in a Sullair air compressor is to control the line pressure either at the inlet or at the outlet, depending on the air pressure applied to it. There are two types of commonly used pressure regulators: the ‘normally closed’, known as a back pressure regulator, and the ‘normally open’ control regulator. Each one is equally important in the pneumatic control circuit.

The back pressure regulator

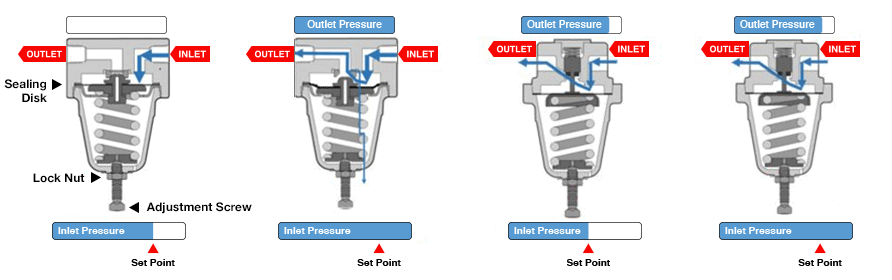

The pressure increase on the inlet of the regulator must overcome the tension of the spring pressure on the sealing disk before the air can flow through to the outlet. Hence, the term ‘normally closed’. This tension can be adjusted by turning the adjustment screw in either direction to set the pressure at which the regulator will operate. (See ‘set point’ in the illustration below). Once the pressure has reached the set point, the outlet pressure will begin to increase. This increase is proportional to the increase in pressure at the inlet. Below are the two states before and after operation.

The control pressure regulator

The basic principle of the control pressure regulator is to keep the outlet pressure constant, even though the inlet pressure may vary. The pressure within the regulator’s inlet increases and applies pressure on the sealing disk. Unlike the back pressure regulator, the air can pass through to the outlet. However, the passage is restricted but not completely blocked; hence, normally open. The adjustment of the screw determines the size of the restriction and how much air can flow through the gap at any given time, therefore reducing or increasing the outlet pressure.

How important are they?

There are several components within the Sullair compressor that rely on the correct functionality of these regulators. These components include inlet valves, spiral valves, and silicon controls. Additionally, they’re not fitted only on stationary compressors – they’re also fitted on portable compressors and vacuum pumps. If the regulator is incorrectly set or malfunctions, the component being controlled will also fail to act to the demand of your compressed air application, which can be very costly. Scheduled preventative maintenance is the key to ensuring that the regulators work correctly.

Interested in finding out more?

Check out Sullair’s full range of air compressor accessories.