Written by Cody Leatherman and Hitachi Global Air Power

When it comes to flooded rotary screw compressors, essential consumable parts such as air filters, oil filters, and air oil separators require periodic replacement for preventing compressor downtime and to ensure optimal operation. However, a common question arises – is it necessary to opt for Original Equipment Manufacturer (OEM) or genuine parts, or can budget non-genuine alternatives suffice?

Preventative maintenance is critical to sustain your air compressor’s efficiency and lifespan. Regular attention ensures proper functionality, identifies potential issues before they become serious, and contributes to energy cost savings, reduced equipment downtime, and improved safety and durability in your compressed air system.

When it comes time to replace critical components, users might be tempted by the lower cost of some components labelled ‘will fit’. However, OEM or genuine parts are either identical to the original machine parts or precisely manufactured replacements.

OEM parts are engineered to work seamlessly with the entire air compressor system, ensuring optimal performance, guaranteed fit and are typically backed by a manufacturer’s warranty. While paying a lower price may be tempting, there are many reasons why you should choose OEM or genuine replacement components over non-genuine alternatives.

Why invest in OEM air compressor replacement parts?

Non-OEM parts may visually resemble their OEM counterparts, but they are often not manufactured using the same materials resulting in less durability, operational inconsistency, lower efficiency, and potential safety risks.

Equipment durability and efficiency

OEMs use the latest engineering methods and optimal manufacturing processes to design and manufacture parts. Non-OEM parts, although designed to look like OEM parts, are often made with different materials. Non-OEM parts not explicitly designed for their intended equipment, carry a higher risk of failure, and are typically less durable. In contrast, OEM parts are designed for peak performance, often for extended periods, minimising interruptions in runtime and reducing the need for frequent repairs.

Stringent quality tests for consistent operation

OEM parts are purposefully designed and subjected to endurance tests to guarantee performance throughout the part’s lifespan. OEM parts meet rigorous quality standards, and their functionality is difficult to replicate.

Safety of users

Safety is a critical consideration; OEM parts follow industry-standard safety compliance processes, ensuring secure manufacturing methods and environmental protection. Non-OEM parts, lacking specific design and testing for the air compressor, may pose a safety hazard in your operations due to potential component failures.

OEM vs. ‘will fit’ oil filters by the numbers

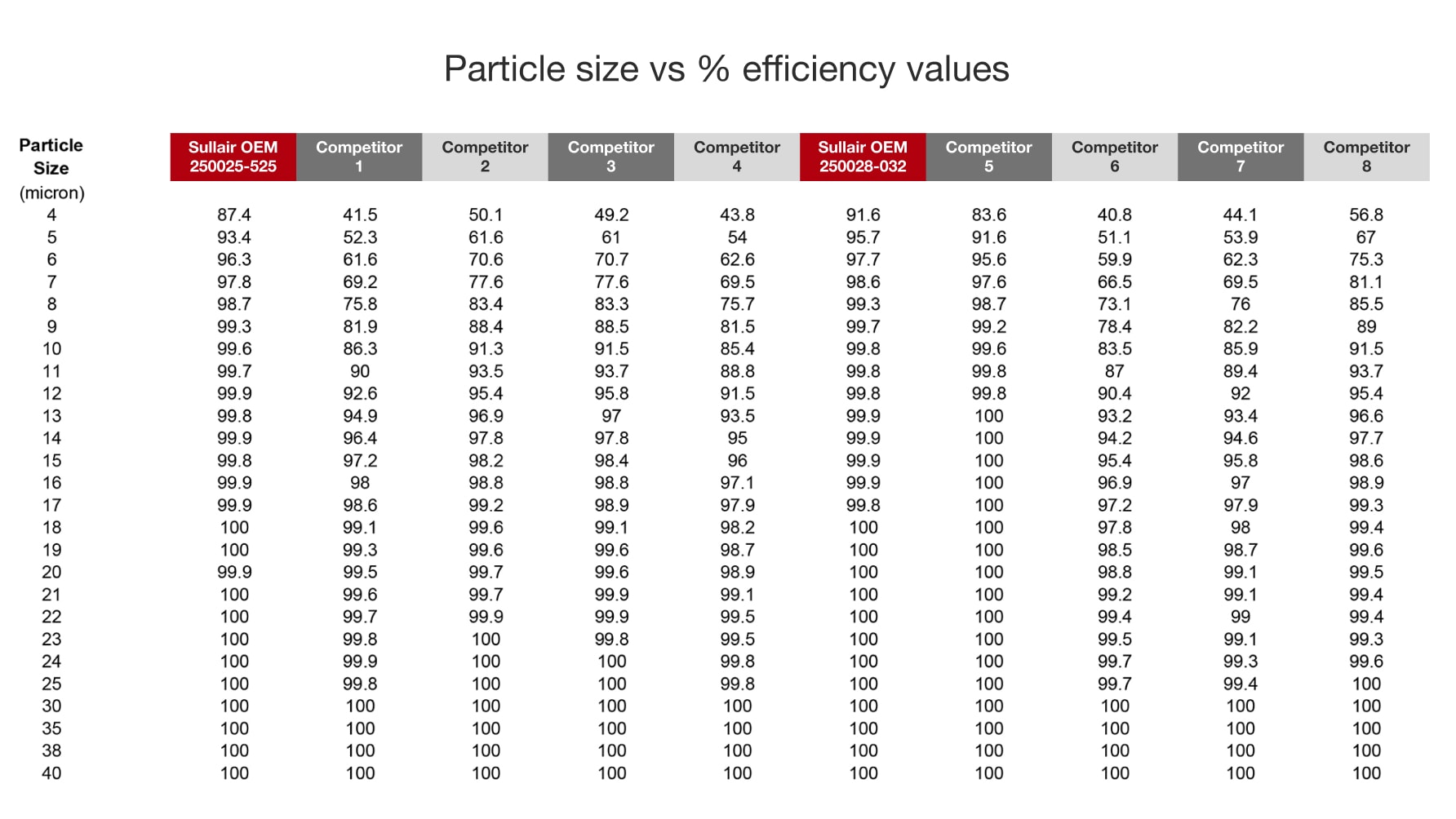

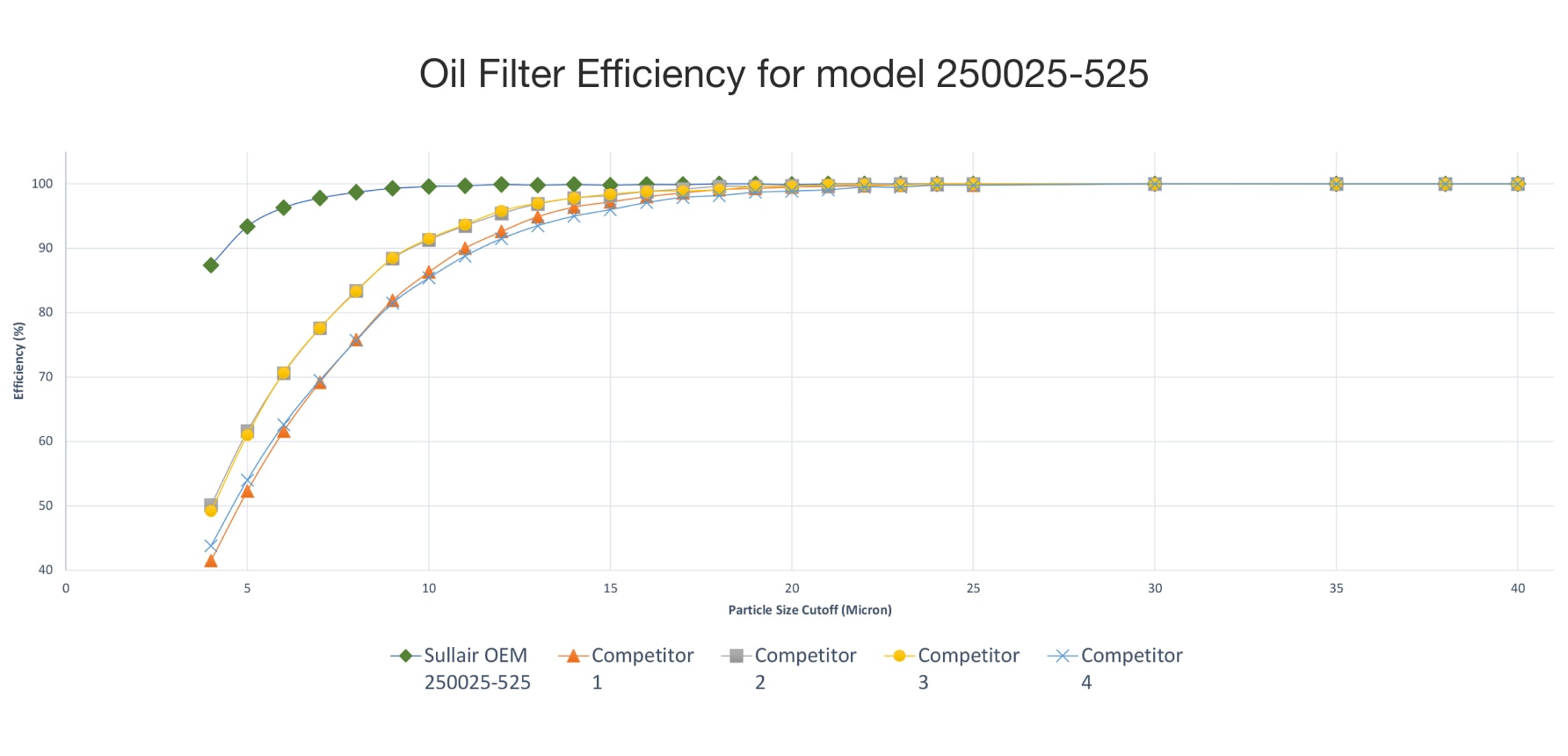

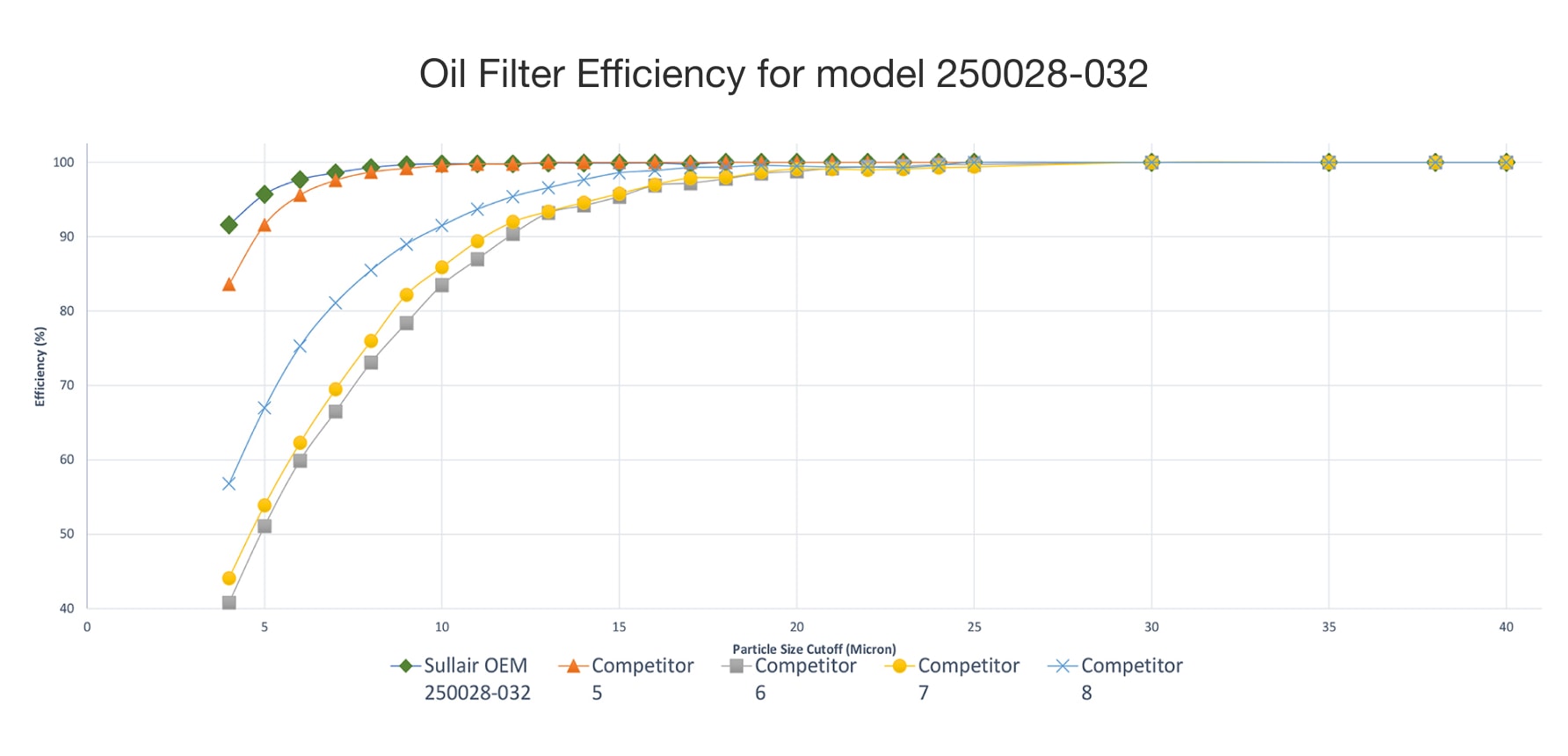

Oil filters are commonly replaced components that can be swapped with OEM and non-OEM alternatives. A multi-pass test was conducted in an ISO 16889 testing company filtration lab, comparing the efficiency of OEM and ‘will fit’ oil filters. Different Sullair oil filter models were tested alongside four non-OEM aftermarket parts corresponding to each Sullair filter model, and the results were compared with genuine Sullair OEM filters.

For the ISO 16889 (multi-pass) test, standard test oil was circulated through the filter in a closed loop system multiple times while test dust was injected into the oil stream. Particle counts were recorded upstream and downstream of the filter; the counts were used to calculate the filter efficiency. The Sullair genuine oil filters outperformed non-OEM aftermarket replacements, with one Sullair OEM model performing about 62% better on average, and the other Sullair OEM model filter surpassing non-OEM alternatives by 89%. Notably, OEM Sullair filters were significantly more effective at filtering out tiny particles that could impact a compressed air system’s functionality over time.

Non-OEM parts are not specifically designed for the compressor and are typically of lower quality and can potentially harm the compressor in the long run. Consider OEM parts as an investment in your business. Replacing worn-out parts with OEM-designed replacements will better protect your air compressor, ensuring its longevity and efficiency.

Interested in finding out more?

Contact us today to find out how OEM replacement parts can improve your compressor’s performance.