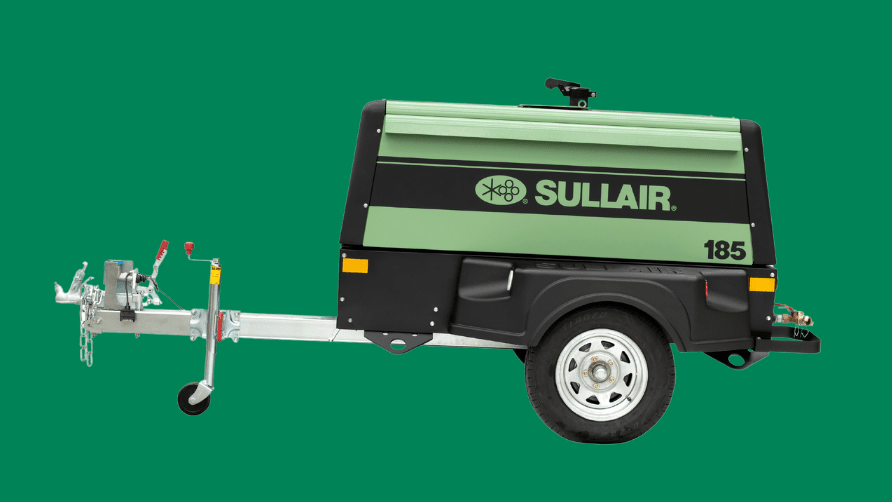

For many of our customers, the key challenge in delivering products or services is doing so in some of the most unique and challenging environments Australia has to offer. Enter the 185A portable lubricated rotary screw compressor: the (new and improved) workhorse of Sullair’s elite mobile fleet.

The 185 compressor has long been the MVP of our portable range of machines. Its compact, flexible design has made it an essential piece of equipment in worksites across the country. With so many people using it in such a variety of ways, we’ve been fortunate to receive a tonne of great feedback that we’ve fed into the design of the next generation model of the same machine – the 185A.

Like the previous model, this machine still offers the same compact unit with the same output, but it has been rebuilt with adaptable design in mind. Nashaat Bakhit is Key Account Manager for portables at Sullair Australia. “Adaptable design means it’s not built for a specific industry or certain areas, it’s designed to be suitable for any environment”. This adaptability is reflected in the fact that the 185A is now smaller, lighter, and mightier than the previous model. Design modifications such as the fully-bunded, clamshell canopy with components that are easy-to-reach for service; relocation of the heat generating exhaust on top of the machine rather than at ground level; and replacement of the analog controller with telemetry in a digital version, (to name a few), make this machine primed and ready for anything.

“What we keep hearing from customers is about the reliability of the Sullair machines”, says Nashaat. “They operate really well in hard environments such as dirty mine sites, and in hot and dusty areas like north Queensland and the NT. The build of the machine is so robust it can operate anywhere in the country without overheating”. This is great reassurance for farmers, especially during times of intense demand and climatic change, such as harvest season. The new 185A offers greater fuel efficiency too, giving it a longer running time – an important drawcard when equipment needs to be well away from a power source or fuel supply for hours on end. A diversion for refuelling can have a significant impact on harvest or production schedules. The smaller, lighter model also provides cost savings on fuel expenses for towing vehicles, whether they’re towing a single compressor, or a trailer stacked with multiple units.

Compressors like the 185 are an essential source of energy in locations and environments where power is unreliable, or even unavailable. From powering pneumatic gear for manual work around the farm, to equipment used for processing of raw materials, their role in the Australian agricultural industry cannot be underestimated.

This reliability and versatility is what makes the 185A such a coveted unit for the hire and rental industry too. “Having the freedom to drive or tow them to site, do whatever the job is that needs to be done for a day, a week, a month or more, then take it off site and return it is a game changer for business”, explains Nashaat. The built-in telemetry will certainly transform the way many hire and rental companies manage their equipment. “It provides the owner of the machines with key information such as where they are and how many hours each unit has been running for”. The digital control means easier operation, reduced risk of faulty parts, and better monitoring capabilities of things such as fuel and oil levels and logged hours (allowing owners to better anticipate service requirements). Indicators such as these are also extremely useful when dealing with multiples of units, as the built in monitoring capabilities enable streamlining of essential daily maintenance. For hire and rental companies that have millions of dollars of equipment in their fleet, shipped out to remote and often unpredictable locations, the benefits are immeasurable.

The Sullair 185A still contains many of the same components as the previous model, delivering compressed air with the same safe, reliable, and efficient output that Sullair is known for.